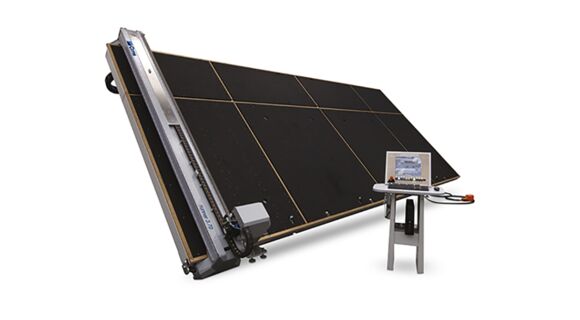

Cutting tables and cutting lines

CMS Glass Technology cutting tables and lines are the ideal solution for cutting flat monolithic and laminated, shaped or straight glass. This range is characterized by NC synchronized brushless motors with features that reduce positioning errors due to

mechanical elasticity. The structure of these machines allows an easy loading/unloading of the biggest glass sheets. In-line cutting, with loading, cutting and breakout, guarantees much higher productivity as it avoids downtime due to the loading and unloading phases

typical of tilting cutting tables. The latest generation of machines stands out for the high quality and precision of the

shaped cutting of the glass, from minimum to heavy thicknesses.